Tue 28 Feb 2006

Walthers 90′ Turntable

Posted by Daniel Swearingen under Layout Progress , Product Review , Turntable[2] comments / Leave a comment

During initial track planning I specified an 80′ turntable at Tiburbon. Eighty feet looked long enough given the types of engines I wanted to run. This worked out to 11 inches in diameter and this felt ok given the overall size of the scene.

The plan was to scratchbuild the turntable but those of you who have done this before know: it’s really easy to build a turntable badly. Fortunately, I realized this immediatly after casually cutting a rough 11 inch diameter hole in the main track sheet of Tiburbon.

First: a rough hole will not do the job.

Second: it became clear that a precisely built and aligned pit, bridge, and approach tracks are required or I will be very sorry indeed.

Third: since this turntable is in the IMMEDIATE foreground of the scene it must be tidy looking.

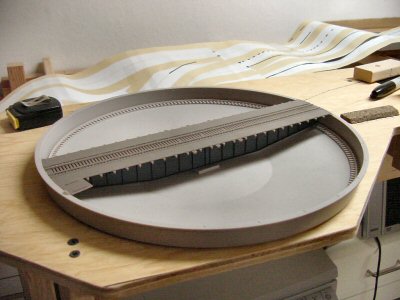

Enter the Walthers 90′ Turntable kit (unpowered) on sale for $31.98.

I’ve had spotty to poor experiences with Walthers plastic kits but I figured for $32 I’d get at least a few pieces I could use. So far it looks great. Simple and tidy. With some easy modifications will turn smoothly. I plan on turning by hand since the table is right at the edge (will I regret this?).

I’ll have to enlarge the existing hole but it basically fits and now I can turn a USRA 2-8-2 Mikado if I want. I’ll post details on cutting and installation soon.

May 9th, 2006 at 4:44 pm

I gave up on the motorization of this turntable because I never could stop the turntable in alignment with the mating rails. When I set it up to turn mauallly, it has so little friction it moves out of position.

Have you found either of these situations and have you found any good solutions?

Allan

May 9th, 2006 at 4:49 pm

Hi Allan:

I plan on using a 1/4″ headphone jack as the main axle and the way power will be communicated to the rails. Turntables are hard. I made my own when I was a teenager and it was poorly aligned and pretty miserable. I had a hand turned worm-drive but still had to wiggle the last millimeter by hand.

You can see why the automatic ones are so much $$$.

Dan